KROFTA ENGINEERING LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KROFTA ENGINEERING LTD.

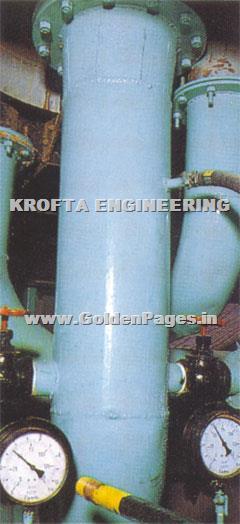

Dry Scrubbing

In 'dry scrubbing' a solid sorbent is injected into the gas stream which reacts with the contaminant and is removed on a filter, together with any other particulates. This produces a dry powder for disposal.

Alkalis such as lime or sodium bicarbonate are injected for the removal of acid gases such as SO2 and HCl. Powdered Active Carbons can be injected to remove heavy metals and trace organic compounds such as dioxin.

Thermal Oxidation

Thermal oxidation is the incineration of solvents, hydrocarbon vapours, fumes and odours, The temperature of the waste gases is heated to between 750oC and 1100oC by a gas or oil fired burner.

In the Recuperative Thermal Oxidiser, up to 60% of the energy can be recovered by using hot gases from the combustion chamber to pre-heat the incoming fume in gas/gas heat exchanger, thus reducing the amount of support fuel consumed.

The Regenerative Thermal Oxidisers can recover up to 97% of the thermal energy and offer considerable saving in the fuel used, and in many cases can reduce the fuel consumption to zero.

Where it is appropriate, further heat can be recovered in the form of hot air, heat transfer oil or steam.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.